EC (Electronically Commutated) ERV (Energy Recovery Ventilation) units are highly efficient ventilation systems that incorporate advanced motor technology, offering precise control, energy savings, and compatibility with Building Management Systems (BMS). BMS integration is crucial for optimizing the performance of HVAC systems in commercial and large residential buildings. Here’s a detailed explanation of how EC ERV units achieve BMS compatibility:

1. Modbus and BACnet Communication Protocols

For an EC ERV unit to be BMS compatible, it must support communication protocols like Modbus, BACnet, or other similar standards. These protocols allow data exchange between the ERV unit and the central BMS, facilitating remote monitoring and control.

- Modbus: A widely used communication protocol in industrial automation systems. Many EC ERV units are equipped with Modbus communication, which allows them to send data like fan speed, airflow rates, temperature, and filter status to the BMS. The BMS can also send control signals back to the unit to adjust these parameters.

- BACnet: Another commonly used protocol in building automation that allows multiple devices (such as sensors, thermostats, and ERV units) from different manufacturers to communicate with each other. EC ERV units that support BACnet can easily be integrated into a BMS that controls other building systems, such as lighting, heating, and air conditioning.

- LonWorks: Some systems may also use LonWorks protocol, which is another standard for smart building systems, although Modbus and BACnet are more common.

2. EC Motors and Variable Speed Control

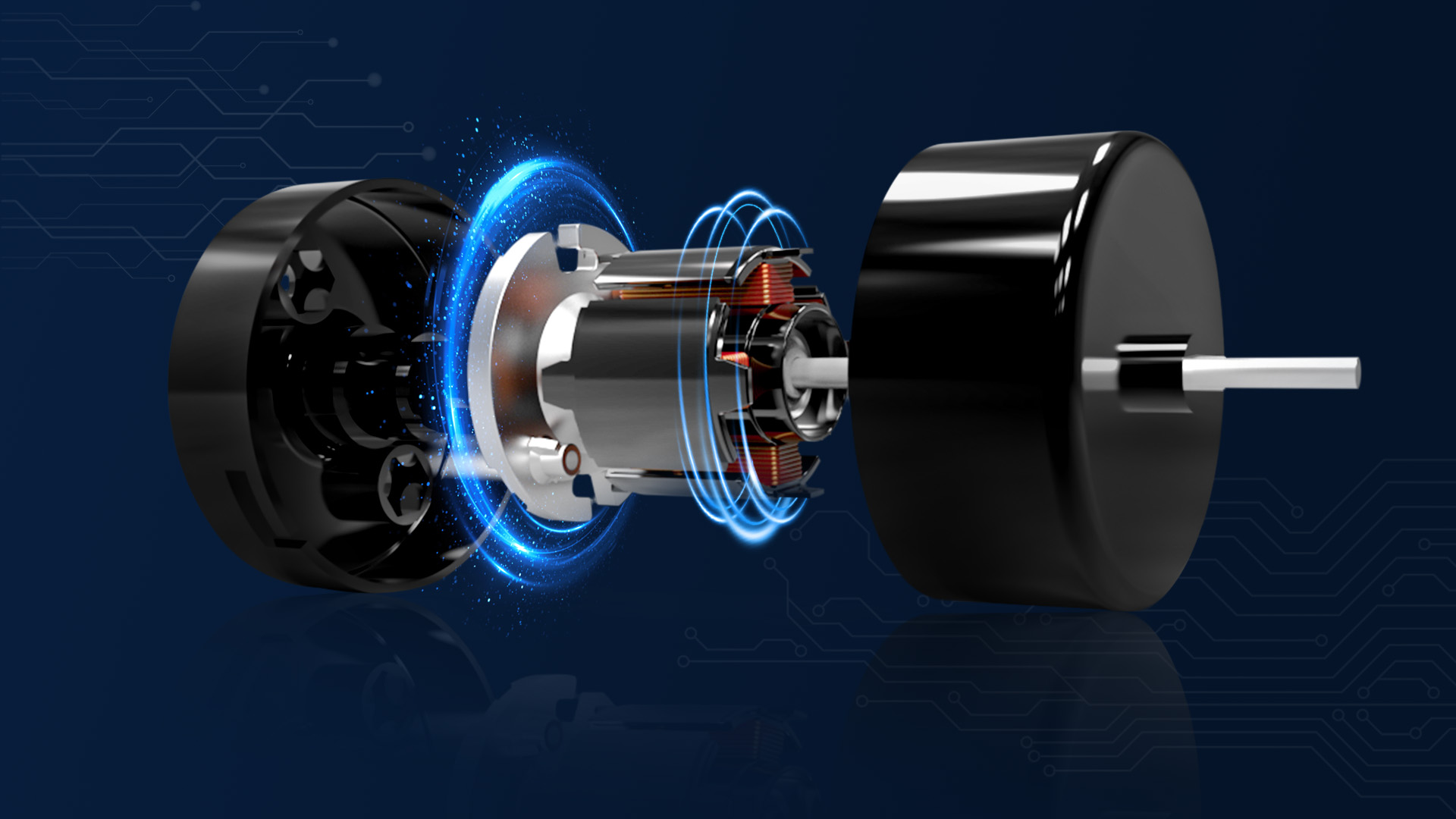

The Electronically Commutated (EC) motors in these ERV units play a crucial role in BMS compatibility. EC motors are highly energy-efficient and provide precise control over the fan speed and airflow. The key to BMS integration is that the motor’s performance can be monitored and adjusted remotely through the BMS interface.

- Variable Speed Control: EC motors allow for variable speed control, meaning that the fan speed can be adjusted based on real-time requirements. For example, if the BMS detects low CO2 levels or temperature changes, it can automatically reduce the fan speed to save energy, or increase it if the system detects poor air quality or rising temperatures.

- Feedback Signals: EC motors in these units often provide feedback signals such as RPM (revolutions per minute) or power consumption data to the BMS, allowing operators to monitor and ensure optimal performance.

3. Built-in Sensors and Monitoring Capabilities

Many EC ERV units come equipped with built-in sensors to monitor various environmental and operational parameters. These sensors can be linked to the BMS for comprehensive building control and automation.

- CO2, Temperature, and Humidity Sensors: The EC ERV unit can monitor indoor air quality (IAQ) metrics such as CO2 levels, temperature, and humidity. These readings can be relayed to the BMS, which can then optimize the ventilation system by increasing or decreasing airflow, improving both energy efficiency and occupant comfort.

- Pressure and Airflow Sensors: These sensors measure static pressure and airflow to ensure that the ventilation system is running at optimal efficiency. The BMS can detect issues like blockages or filter clogs and alert the building maintenance team or automatically adjust the fan speed to compensate.

- Filter Monitoring: EC ERV units often include filter monitoring systems that can alert the BMS when the filter needs cleaning or replacement. This feature helps to maintain good air quality and system efficiency.

4. Energy Monitoring and Optimization

One of the significant advantages of BMS compatibility is the ability to track and optimize energy usage. EC ERV units can send real-time data about energy consumption, fan speed, and motor efficiency to the BMS. This information can be used to fine-tune system operations and reduce energy costs.

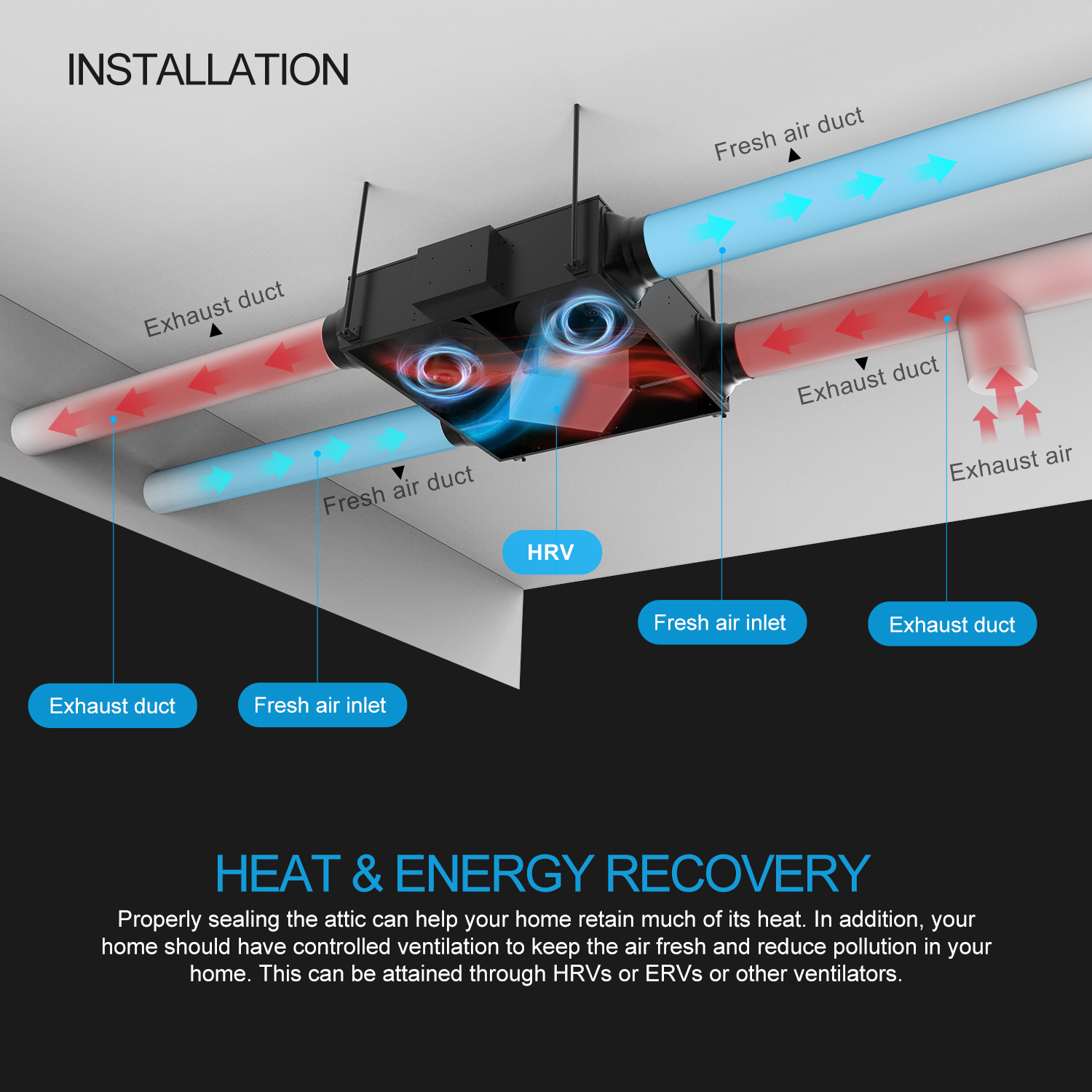

- Energy Recovery Efficiency: ERV systems are designed to recover energy from exhaust air and use it to precondition incoming fresh air, reducing the energy needed for heating or cooling. The BMS can monitor the heat exchange efficiency and adjust the system to ensure optimal energy recovery.

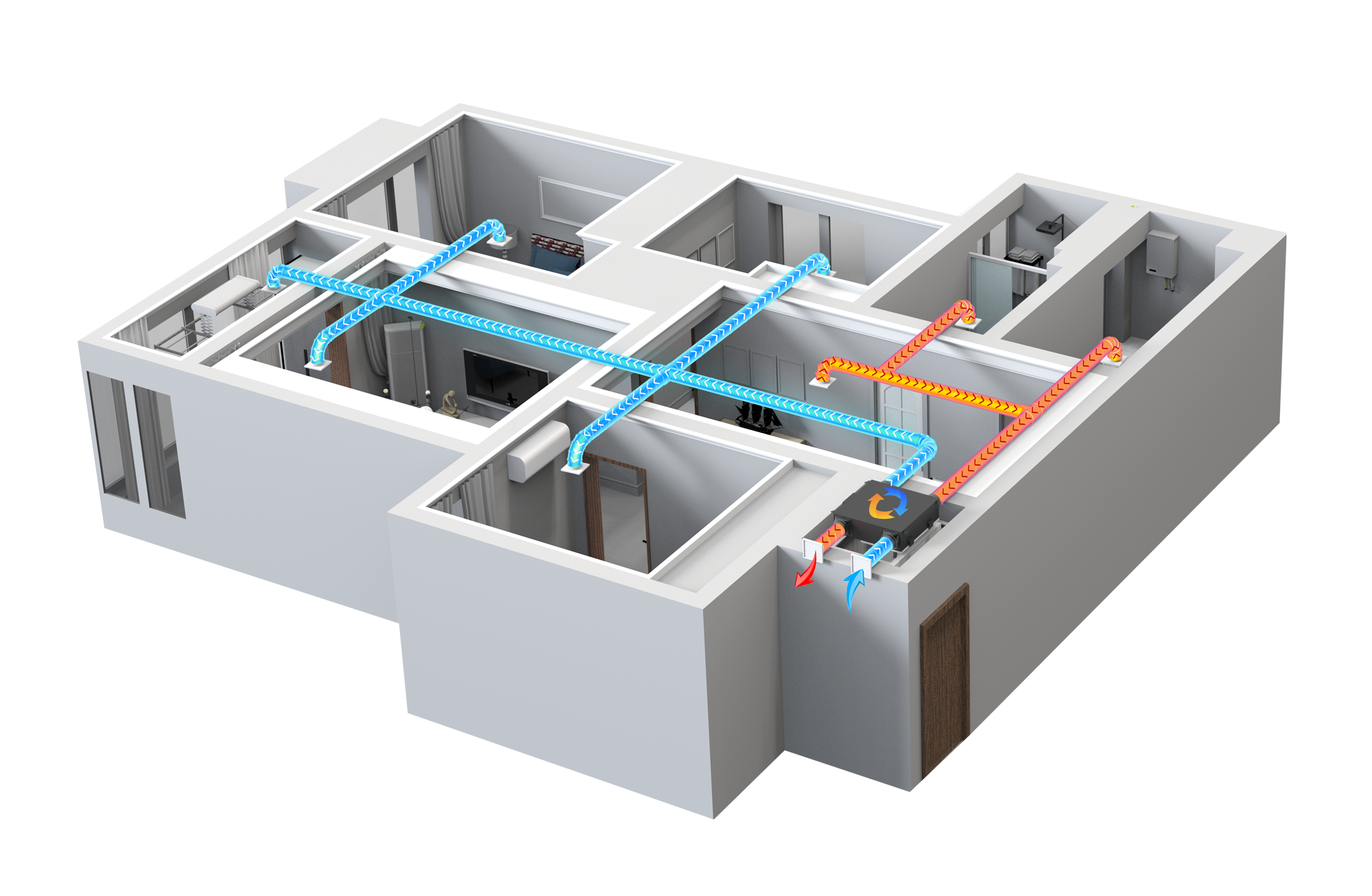

- Scheduling and Load Management: Through the BMS, operators can set up schedules to run the EC ERV units at certain times or in specific zones, reducing unnecessary energy use during off-peak hours or in unoccupied spaces.

5. Remote Monitoring and Control

A critical feature of BMS integration is the ability to remotely monitor and control EC ERV units. This is particularly beneficial for large buildings or campuses where HVAC systems are spread across multiple floors or locations.

- Remote Diagnostics: Through the BMS, building operators can access detailed diagnostics about the ERV system, such as fan motor status, filter conditions, and airflow performance. This helps identify problems early, enabling proactive maintenance and minimizing downtime.

- Centralized Control: The BMS provides a centralized platform to control multiple EC ERV units. Operators can adjust the ventilation settings, turn units on or off, and respond to environmental changes in real-time across the entire building or facility.

6. Fault Detection and Alerts

EC ERV units often have self-diagnosis capabilities that can communicate directly with the BMS. If the unit detects a fault, such as a motor malfunction, filter blockage, or airflow problem, it can send an alert to the BMS. This allows maintenance teams to address issues promptly, improving system reliability and preventing costly breakdowns.

KCVNETS EC ERV units are highly compatible with Building Management Systems, thanks to their advanced motor control, built-in sensors, and support for communication protocols like Modbus and BACnet. Through BMS integration, these units provide real-time monitoring, remote control, and energy optimization, helping building operators maintain optimal indoor air quality while minimizing energy costs. When equipped with BMS connectivity, EC ERV systems offer a seamless and smart solution for modern building automation and sustainability.